Temperature and dry well calibrators

Fluke Temperature Calibrators simulate process sensors for testing temperature instrumentation. Specifically designed for the field, these lightweight compact tools are EMI tolerant, dust and splash resistant and offer an easy to use single push button interface. When paired with a temperature sensor they can take high accuracy temperature measurements to verify process temperatures and ensure the highest product quality and safety. There are a variety of different temperature calibrators designed for your unique calibration and testing requirements.

Fluke offers a wide range of temperature calibration equipment. Everything from simple Stik Thermometers to temperature simulation/measurement calibrators to dry-blocks, micro-baths and metrology wells. Whether you’re looking to calibrate a temperature transmitter in the field, test an RTD sensor, simulate a thermocouple, or calibrate a temperature transmitter at the bench, Fluke has a temperature calibrator for you.

Find the right pressure calibrator

Temperature calibration solutions

There is no one size fits all temperature test tool that meets the requirements of all users performing temperature instrument maintenance.

Our temperature calibration tools product selector can help you choose the right temperature calibrator for the task you need to perform. Use it now

Fluke 9190A Ultra-Cool Field Metrology Well

The Fluke 9190A Ultra-Cool Field Metrology Well is the most accurate and stable, cold temperature...

Fluke Calibration 9170 Metrology Well

Combining bath-level performance with dry-well functionality and legitimate reference thermometry,...

Fluke Calibration 4180/4181 Precision IR Calibrators

Now it’s easy to increase your IR temperature measurement accuracy with the new 4180/4181 Hart...

Fluke Calibration 6109A / 7109A Portable Calibration Baths

The Fluke Calibration 6109A and 7109A Portable Calibration Baths let process industry professionals...

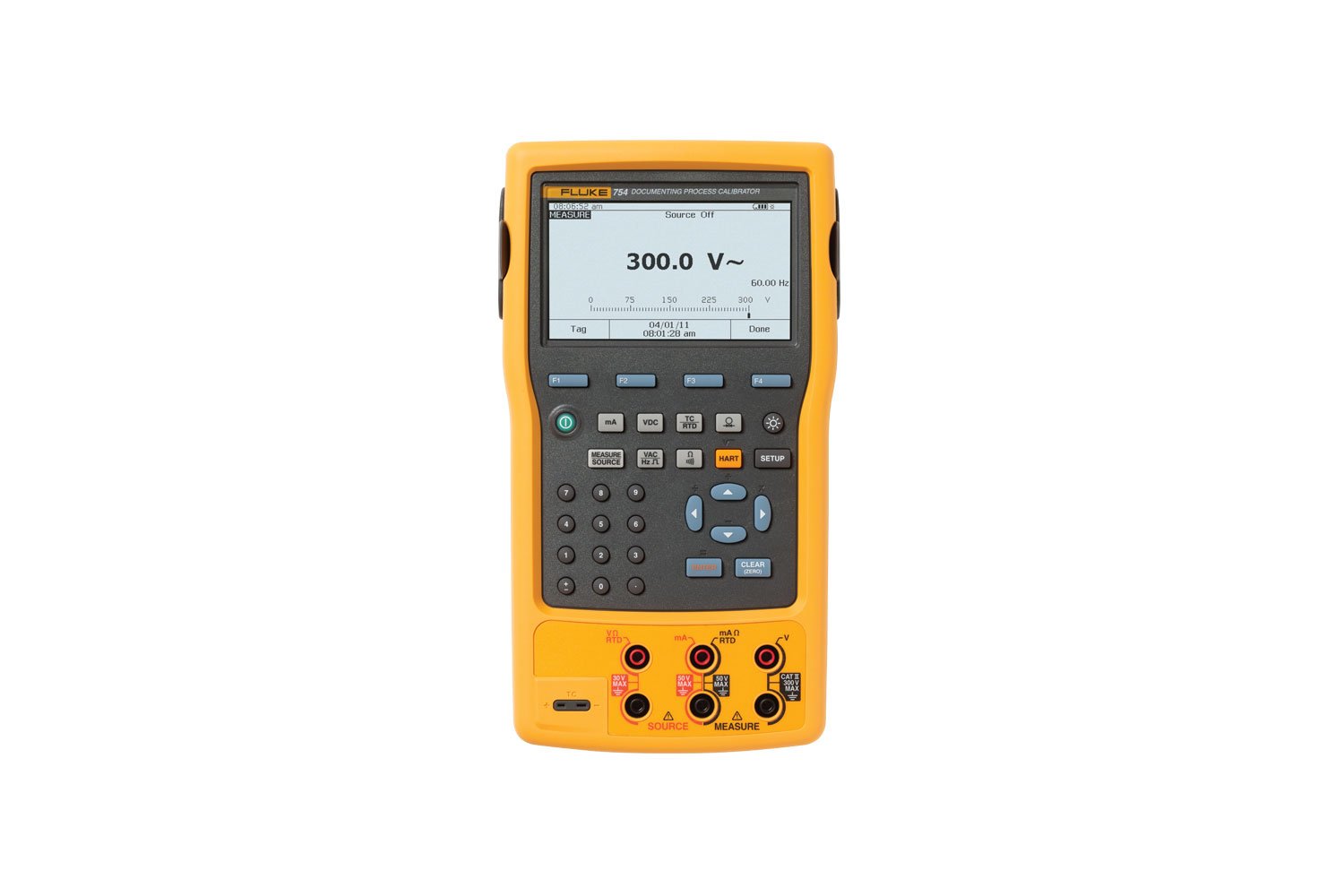

Fluke 753 Documenting Process Calibrator

The 753 does the work of several tools – sourcing, simulating and measuring pressure, temperature,...

Fluke Calibration 9009 Dual-Well Dry-Well

The Fluke Calibration 9009 dry-well offers two independently controlled temperature blocks (-15°C...

Fluke Calibration 9142 Field Metrology Well

The 9142 Series Field Metrology Wells extend high performance to the industrial process environment...

Fluke Calibration 9144 Metrology Well

The 9144 Series Field Metrology Wells extend high performance to the industrial process environment...

Fluke Calibration 6102/7102/7103 Micro-Bath

Hart Scientific manufactures these Micro-Baths for calibration of thermometers and sensors that do...

Fluke 9132/9133 Portable Infrared Calibrator with Blackbody Source

Our portable IR calibrators provide stable blackbody targets for calibrating noncontact IR...

Fluke Calibration 9143 Field Metrology Well

The 9143 Series Field Metrology Wells extend high performance to the industrial process environment...

Fluke 726 Precision Multifunction Calibrators

Calibrate thermocouples and RTD temperature instruments

Fluke Calibration 9103/9140 Field Dry-Well

If you’ve been using dry-well calibrators for field work, you know there’s a lot more to a...

Fluke Calibration 9102S Handheld Dry-Well

Truly portable handheld dry-block temperature calibrators. They’re the smallest, lightest, and...

Fluke Calibration 1502A/1504 Thermometer Readout

The Fluke Calibration 1502A/1504 offers high-accuracy temperature measurement for reference and...

Fluke Calibration 1620A Precision Thermo-Hygrometer

The DewK measures temperature to ±0.125 °C and humidity to ±1.5% on two channels, and displays it...

Fluke Calibration 1524 Handheld Thermometer Readout

The 1524 Reference Thermometers from Fluke’s Hart Scientific Division measure, graph, and record...

Fluke Calibration 9100S Handheld Dry-Well

Truly portable handheld dry-block temperature calibrators. They’re the smallest, lightest, and...

Fluke 714B Thermocouple Calibrator

The Fluke Calibration 714B thermocouple calibrator measures and simulates 9 types of thermocouples,...

Fluke 712B RTD Calibrators

For the temperature calibration professional that wants a highly accurate, easy-to-use, single...

Secondary PRT with Calibration Options - 5608 and 5609

Fluke Calibration 5608/5609 PRT probes are secondary reference standards for precise and stable...

5606 Full Immersion PRT

The Fluke Calibration 5606 immersion PRT probe offers excellent accuracy and stability for...

Fluke Calibration 9172 Metrology Well

9172 Metrology Wells. Now we’ve combined bath-level performance with dry-well functionality and...

Fluke Calibration 9173 Metrology Well

The Fluke Calibration 9173 metrology well provides a highly stable and uniform temperature...

Fluke Calibration 9171 Metrology Well

9171 Metrology Wells. Now we’ve combined bath-level performance with dry-well functionality and...

Fluke Calibration 9150 Thermocouple Furnace

9150 Thermocouple Furnace uses Hart’s own microprocessor-based controller for great stability and...

Fluke 1586A Super-DAQ Precision Temperature Scanner

The most accurate and flexible temperature data acquisition system on the market.

9190A-X-P Ultra-Cool Field Metrology Well

The Fluke 9190A Ultra-Cool Field Metrology Well is the most accurate and stable, cold temperature...

1529 Chub-E4 Standards Thermometer

Fluke Calibration’s 1529 Chub-E4 Thermometer gives you four channels, three major sensor types,...

Fluke 700PCK Pressure Calibration Kit

The Fluke 700PCK makes it possible to calibrate your pressure modules at your facility using your...

Fluke TL80A Basic Electronic Test Lead Kit

Test leads are an integral part of the complete measurement system and extend the capabilities of...