Table of Contents

Why is calibration important?

The importance of calibration in the future

Different perspectives on the significance of calibration

The benefits and purpose of calibration

What are the costs and risks of not calibrating?

Summary / TL;DR

Why is calibration important?

Calibration is important because it helps ensure accurate measurements, and accurate measurements are foundational to the quality, safety and innovation of most products and services we use and rely on every day.

Few people realize the critical role and importance of calibration in their daily lives.

But calibration improves assurance of precise measurements required in research, development, and innovation, as well as the production of millions of products and services worldwide. Pause and look around your room right now; most of what you see was produced within tight measurement specifications assured by calibration.

A shortlist of examples where calibration is quietly behind the scenes assuring precise measurements critical to the comfort, quality and safety of products and innovation we enjoy and rely on daily include:

- All transportation and related systems including cars, trains, planes and gasoline pumps

- All electronics including phones, cell-phone service, computers, appliances, and test and measurement devices

- All pharmaceutical products and medications

- All medical devices like pacemakers and processes like sterilization

- All aerospace and related systems including rockets, satellites and the International Space Station

- Food production, shipping and storage

- Trade of things like oil, grains and gold

- Scientific research, development and innovation

And the list goes on and on in an ever-expanding universe of millions of other services and manufactured goods around the world.

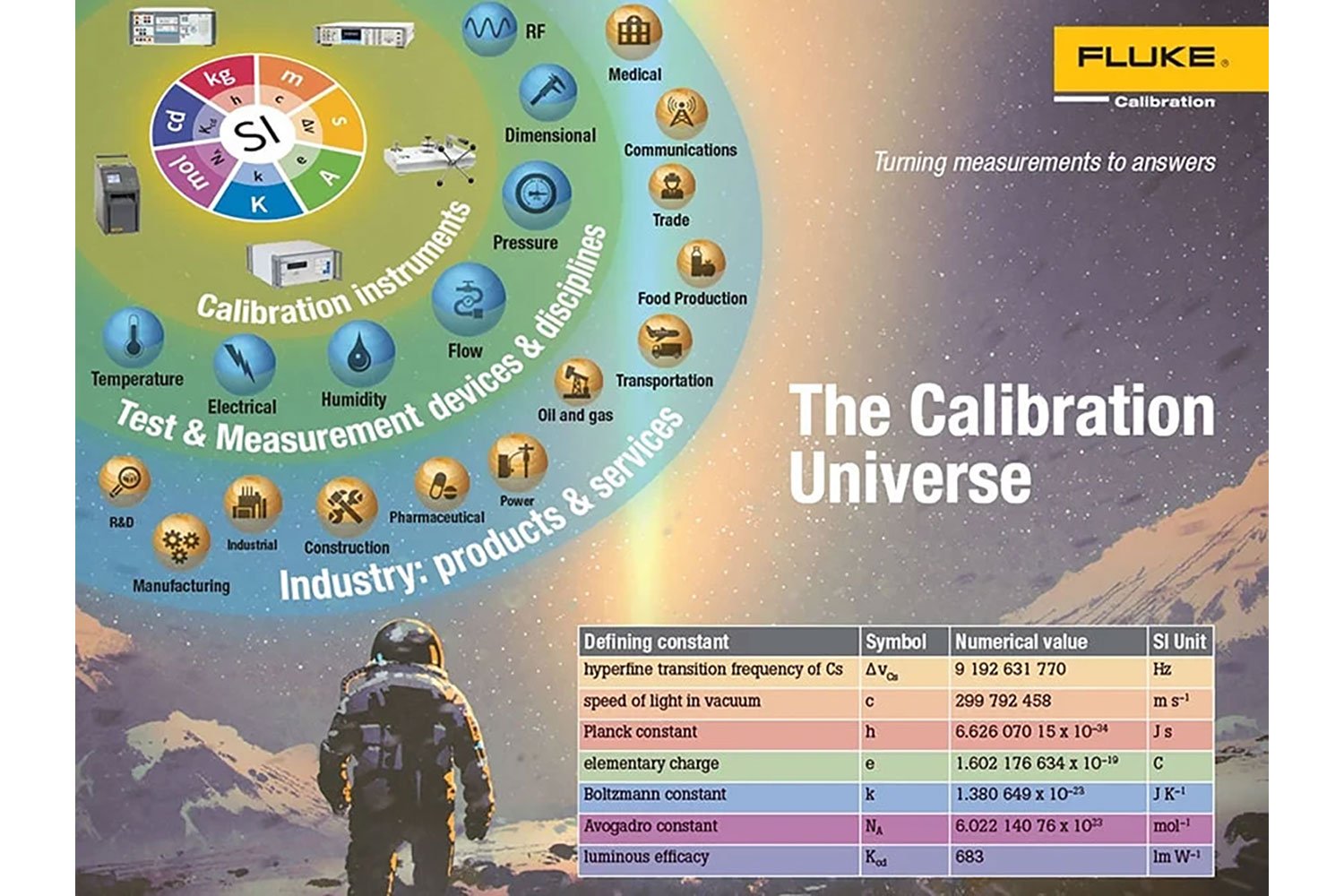

The Calibration Universe diagram that follows helps illustrate the importance of calibration by showing that calibration to the SI (the ultimate measurement standards) is at the center of an ever-expanding universe of products and services. (For more information on the SI see our page About Calibration.)

In The Calibration Universe, products and services are produced to precise specifications with the help of test and measurement devices whose accuracy is assured by calibration to the SI, the ultimate measurement standards

In the outer ring of The Calibration Universe diagram above, millions of products and services, such as computers, appliances, and cell service are produced within precise specifications in virtually all industries including manufacturing, R&D, pharmaceutical, oil & gas, transportation, food production, etc.

As represented in the next ring to the left of the diagram, there are myriads of test and measurement devices such as infrared temperature cameras, multimeters, and motor analyzers deployed within virtually all production measurement disciplines such as temperature, electrical and pressure, to accurately measure and control the production of quality products, services, and technologies.

Test and measurement devices pictured here from left to right are a thermal camera, contact thermometer, power monitor, vibration analysis tool, laser alignment tool, and multimeter

Test and measurement devices pictured here from left to right are a thermal camera, contact thermometer, power monitor, vibration analysis tool, laser alignment tool, and multimeter

Moving to the next ring of the diagram, to assure their accuracy, test and measurement devices are calibrated regularly by more accurate instruments commonly referred to as calibrators and reference standards.

Calibration instruments pictured here include calibrators and reference standards in the measurement disciplines of electrical, rf, temperature, humidity, pressure and flow

Calibration instruments pictured here include calibrators and reference standards in the measurement disciplines of electrical, rf, temperature, humidity, pressure and flow

And finally, at the center of the universe lies the SI, the ultimate measurement reference standards, often based on constants of nature that never change, like the speed of light, and can be realized anywhere in the universe. The calibrators and reference standards are calibrated to the SI.

The SI allows all countries to synchronize to the same universal standards to ensure consistent measures worldwide. In this way, calibration to the most reliable and accurate standards is passed down through an unbroken chain to help assure the accurate and reliable production of products, services, and technologies around the world.

The SI (The International System of Units) are the ultimate measurement reference standards that help assure accurate measurements in the production of millions of products and services we rely on every day

The SI (The International System of Units) are the ultimate measurement reference standards that help assure accurate measurements in the production of millions of products and services we rely on every day

Regarding the importance of calibration, Jeff Gust, Chief Corporate Metrologist of Fluke Corporation, explains, “If you are performing measurement where the results will make a critical decision such as a safety test or if a manufactured product meets requirements, you must have your equipment calibrated so that the performance is known and fit for purpose. This is especially important if you want your results to correlate with others around the world.

“All mechanical parts wear, and all electronic components drift over time, so a measuring instrument will not measure accurately to its specifications forever, it must be calibrated routinely to make sure that it operates properly and makes measurements as per its product specifications, and those results can be duplicated by others around the world because the calibration system is traceable to a common global reference.”

“In short, if measurement results matter, calibration matters.”

Calibration in our daily lives

The next time you turn on a light, drive a car, take medication, use a computer or phone, or use millions of other man-made things, consider that the product or service you’re using likely depended on accurate R&D, measurements, and calibration to deliver the safety, comfort, and reliability we all depend on.

The image below helps illustrate, by industry, the hidden ubiquity, importance, and role of calibration in our daily lives.

Few people realize that calibration of measurement instruments and other equipment to the SI impacts virtually all industries and most products and services we use on a daily basis

Few people realize that calibration of measurement instruments and other equipment to the SI impacts virtually all industries and most products and services we use on a daily basis

The Importance of Calibration in the Future

The importance of calibration only grows in the future. The further we push technology, the more precise measurements need to be and the greater the significance of calibration.

You can get a better sense for the importance of calibration today and the future as you are exposed to the critical measurements required by advanced transportation systems in this 2 1/2-minute video by Jeff Gust, Chief Corporate Metrologist of Fluke:

Video: Jeff Gust explaining the role of accurate measurements and calibration in transportation

In the future, we can expect even more technologically advanced transportation systems, requiring even more precise measurements that need to be assured by calibration. As an example, think of the driverless cars that we are beginning to see on our roads today and that will increasingly be a part of the transportation system of the future. All of us will feel a bit better about driverless cars knowing that the accuracy of their precise measurement systems pass an increased level of assurance provided by calibration.

Different Perspectives on the Significance of Calibration

To more specifically illustrate the importance of calibration, this article will cover the significance of calibration from various perspectives by industries and fields and it will address the benefits and purpose of calibration.

Several examples will be presented here showing the significance of calibration in research and development of new technology, innovation, and equipment maintenance. The importance of calibrating equipment, such as thermometers, will be discussed. The purpose and benefits of calibration will be illustrated in terms of saving money and increasing profitability, improving safety, complying with regulations, and getting a strong Return on Investment (ROI).

Why Calibration is Important – A View by Industry

Let’s look at few examples by some of the industries illustrated in the Calibration Universe graphic above to further demonstrate the significance of calibration.

Trade

Think what would happen to commercial trade if measurements weren’t precise. Without precise measurements assured by calibration, both the seller and the buyer would wonder if they’re getting their fair share in the trade. Would fewer people conduct trade due to the risks? Could trade companies survive the impact of imprecise measurements? Precise measurements assured by calibration allow those who trade in gold, grain, oil and millions of other products to be confident in transactions and to run their local or global businesses with reliable information. Thanks to calibration programs, you don’t have to think much about buying a gallon of gasoline or an ounce of gold.

Pharmaceutical

How comfortable would you be taking medication if quantity measurements weren’t frequently calibrated? Additionally, many medications must be manufactured within tight temperature and humidity tolerances to be effective and non-harmful. Did you know that even a pipette that measures out drops of liquid in a pharmaceutical manufacturing process is calibrated? Calibration allows billions of people around the world to take medications with assurances of effectiveness and safety.

Medical

To further illustrate the importance of calibration, consider the life-giving and life-improving impacts that medical devices like pacemakers have on millions of people worldwide.

A Boston Scientific pacemaker made to exacting specifications with the help of test and measurement devices whose accuracy has been assured by calibration to the SI

A Boston Scientific pacemaker made to exacting specifications with the help of test and measurement devices whose accuracy has been assured by calibration to the SI

Mike Imholte, Sr. Calibration Technician at Boston Scientific, a manufacturer of pacemakers, explains, “When you realize a pacemaker goes inside a person’s chest and connects directly to the heart, it’s easier to understand why a properly working and reliable pacemaker requires many precise measurements and tests. And to make sure our testing devices and manufacturing equipment is producing within very tight measurement tolerances, we regularly calibrate them with the best quality calibrators. Given the criticality of meeting specifications, we need to have the assurance that calibration provides throughout the entire manufacturing process. This is why calibration is necessary.”

Mike recalls when one of their pacemaker customers visited Boston Scientific to express appreciation for his pacemaker. Mike says that the customer was in his early 30’s before he got his pacemaker. His heart was in such bad shape that a trip from his home living room to his bathroom required a chair in the hallway to sit and rest on the way there and back.

This same person went from that poor shape to immediately feeling a surge in energy right after pacemaker surgery. Now the customer enjoys the normal things in life most of us take for granted, like playing with his kids outside.

Unlike most of the world who aren’t aware of the importance of calibration and don’t understand why it is important to calibrate, Mike says, “the significance of calibration can’t be overstated. Our testing tools and manufacturing processes must be accurate. Both we and millions of people with pacemakers, whether they realize it or not, rely on calibration for that purpose.”

Transportation

Think of the billions of people around the world who rely on automobiles, trains, and planes for travel every day. Then consider the thousands of pieces that make up the cars, trains, and planes. It’s mind-boggling to think about but doing so can increase appreciation for the role and need of calibration.

Without the assurance of calibration, how discomforting would it be to look out a plane window and wonder if the bolts and rivets that hold things together were manufactured to exacting metallurgical and mechanical specifications? With proper calibration of test and measurement devices, manufacturing equipment, guidance systems, and processes, you can feel quite assured on your next plane ride that you’ll arrive safely at your precise destination.

Aerospace

Not much imagination is required to guess at the need for calibration in the aerospace industry. The manufacture of planes, rockets, and satellites requires millions of pieces for assembly which each need to perform as specified to avoid disaster.

Airplanes, rockets and satellites are assembled from millions of pieces that have been produced to precise specifications with the help of calibrated manufacturing equipment

Airplanes, rockets and satellites are assembled from millions of pieces that have been produced to precise specifications with the help of calibrated manufacturing equipment

Test and measurement devices used in design, testing, and manufacturing help ensure that manufacturing equipment and processes perform as specified to turn out a final product that works as designed. To verify their accuracy, the test and measurement devices are calibrated by more accurate calibrators and reference standards that are calibrated to the SI. In this way, we have increased assurance that measurements in manufacture and assembly are accurate and reliable.

An example of why calibration is important in the aerospace industry is provided by the International Space Station.

One of the many important safety features of the space station is the ability for the astronauts to see out the windows. Because the temperature of space is about -270 degrees Celsius, the outside of the window is very cold. Inside the space station, the air is warm and humid, so the astronauts are comfortable. If the humid air meets a window at -270 degrees Celsius, ice would form as the water vapor in the air freezes on the window eventually damaging the space station and obscuring views of the outside.

To prevent that problem, the windows are heated and monitored by a temperature sensor on the window. The temperature sensor is tested with a Fluke test and measurement device. In turn, the test and measurement device is regularly calibrated by a calibrator, which is calibrated to the SI. In this way, all have confidence that the sensor is operating properly so that systems keep the window functional, contributing to the safety and success of the space station astronauts.

Why calibration is important – a view by professional field

Now let’s look at the need for calibration in a few professional fields.

Why is calibration important in the scientific laboratory?

Calibration is important in the scientific laboratory because research is expensive and also foundational to innovation; non-accurate scientific measurement instruments can yield incorrect results and conclusions causing expensive errors.

Such was the unfortunate case for a couple of scientists at the University of Utah back in the late 1980s. The scientists announced they had observed a cold fusion reaction, but to the great embarrassment of the university, later tests proved they had not. The science community criticized the scientists for lack of controls. As a result of this event, more energy research laboratories adopted strict calibration programs to ensure that their instruments used in testing and research would never cause faulty readings or lack of controls.

Why is calibration important in chemistry?

Calibration is important in chemistry because precise chemical amounts and environmental conditions are often required for successful product creation and delivery.

As a simple example, think of your last baking failure. If the scales on which you weigh ingredients are off by much, you probably know from personal experience that the outcome can be less than ideal.

Vaccinations offer a more technical example. The Center for Disease Control (CDC) has a big, complex job in creating and delivering vaccinations. Vaccinations need to be made with precise compositions and kept within certain temperatures to remain effective and safe.

Also, today there are very expensive cancer drugs that are custom made for patients which can cost thousands of dollars per dose. If the drug gets too warm before use, it may become ineffective. Temperature range requirements for the delivery of drugs and other products have given rise to recent increases in cold chain management where temperature sensors are regularly calibrated to help assure accurate readings from manufacture to storage to shipping, whether by plane, train, truck or mail. While the end user of the drug may give little thought to calibration, the manufacturer and all involved in the distribution chain are well aware of the importance of accurate measurements assured by calibration.

The Benefits and Purpose of Calibration

The purpose of calibration is to help assure precise measurements.

The benefits of calibration include increased profitability, safety, and innovation as well as improved compliance with environmental and other regulations.

Calibration helps increase profitability

Generally, profitability can be increased by either increasing revenues or cutting costs; calibration helps do both.

Calibration helps increase revenue

Calibration helps increase revenues by helping manufacturers and service providers produce quality products and services that get good customer reviews and loyal customers.

Calibration helps cut costs and save money

Calibration helps cut costs by reducing production errors and recalls.

Calibration of equipment can help save money by avoiding false acceptance and rejection of product and by extending the life of manufacturing equipment.

Why is it important to calibrate equipment?

It is important to calibrate equipment to help assure accurate measurements and production of quality products with reduced errors and recalls. It is also important to calibrate equipment to foster innovation and the development of new technologies, as accurate measurements are foundational to both.

An industrial calibrator calibrating test and measurement equipment

An industrial calibrator calibrating test and measurement equipment

Of course, importance is relative. The importance of calibrating equipment can range from burning or undercooking your food to the success and safety of the International Space Station.

To illustrate why it’s important to calibrate equipment and how it can save money and increase profitability, let’s look at an example of why it’s important to calibrate a thermometer.

Why is it necessary to calibrate a thermometer?

It is necessary to calibrate a thermometer to assure accurate readings, as the accuracy of a thermometer can drift over time.

Thermometers can drift over time for various reasons. One reason a thermometer can drift is mechanical shock. Highly accurate thermometers, like standard platinum resistance thermometers (SPRTs), contain delicate sensors at their tips that can malfunction from mechanical shock caused by improper handling. Sometimes, people in the shop or lab aren’t aware of the need to carefully handle thermometers and end up banging them against things, and even treating them roughly like common tools in a toolbox.

Another reason a thermometer can drift is exposure to extreme temperatures. Some organizations need to measure extremely cold temperatures in the middle of a large freezer. They sometimes incorrectly place the entire thermometer in the freezer. While the probe portion of the thermometer is rated for the extremely cold temperature, the handle usually is not. Exposure of the handle to the extreme temperature can cause the thermometer to drift.

Exposure of the thermometer handle to extremely high temperatures can also cause the thermometer to drift. One way the handle can get too hot is during a calibration itself. If calibrating at an extremely high temperature, such as 600 degrees Celsius, in a dry-well furnace, care needs to be taken to shield the handle.

These are some of the reasons that thermometers can drift and why it’s necessary to regularly calibrate them.

An industrial calibrator using a reference probe to calibrate a thermometer

An industrial calibrator using a reference probe to calibrate a thermometer

An example of why calibrating a thermometer can save money and increase profits

One pharmaceutical manufacturer learned the hard way about the significance of regularly calibrating and checking thermometers used in one of their drug manufacturing processes.

The pharmaceutical company was not aware that reference thermometers could drift and lose original accuracy. The company used its reference thermometer to calibrate process thermometers within a tight temperature range required to make their drug effective. Once they realized it needed calibration, they sent the thermometer out for calibration and discovered it was out-of-tolerance to the point that all associated products had to be scrapped which cost the company about $1 million. They were quite distraught. Later they learned that with some additional knowledge about thermometers and with some basic measurement checks and better calibration management, the company could have avoided the $1 million hit to their profitability.

Avoiding the costs of false accept and false reject with calibration

The pharmaceutical company in our above example experienced a false acceptance of product. False acceptance of product is where the product, or the product manufacturing process, is out of specification but nothing indicates, and no one knows, that it is out of specification. False acceptance is particularly costly because the bad product is shipped causing large costs in handling the recall as well as damage to the product and company brand. Perhaps the biggest risk is the potential of a faulty product being used by consumers and causing harm to the consumer and liability to the company.

Conversely, false rejection is where the product is produced within specification, but erroneous measurements falsely report it as out of specification. Good product is wrongly scrapped at the expense of the organization’s profitability.

The concepts of false accept and false reject are becoming more prevalent as companies seek to efficiently increase profitability and be competitive. Well managed calibration programs can help manufacturers become more efficient while also improving quality and reducing risk.

Calibration saves money by increasing production efficiency

An efficient production process, free of mechanical shutdowns, helps improve profitability. Calibration saves money by ensuring test and measurement devices measure accurately and properly detect potential manufacturing problems before they happen. Problems can be proactively remedied during normal maintenance times rather than waiting for failures that cause production shutdowns.

Calibration saves money by extending the life of equipment

Calibration helps extend the life of various instruments and manufacturing equipment. Consider how ubiquitous motors are in the manufacturing industry. Over time, the rotating parts of a motor can become imbalanced and misaligned. If not diagnosed quickly by calibrated, accurate test and measurement devices, the motor can fail unexpectedly. A calibrated and accurate vibration monitor or infrared thermometer will detect problems early so that an inexpensive tune-up can avoid costly replacement. As an example, watch this Fluke video on preventing common motor issues.

Technician applying vibration monitoring equipment to a motor

Technician applying vibration monitoring equipment to a motor

For another example, consider the precise requirements of manufacturing tiny computer chips. Due to extremely tight manufacturing tolerances, computer chip manufacturing equipment uses test probes that are so small they’re almost microscopic. The manufacturing equipment is calibrated regularly because getting the probes to touch the chips correctly requires super precise measurements. Without precise measurements assured by calibration, things would start knocking into each other and breaking during production, causing expensive factory line or cell shutdowns.

Calibration delivers a high return on investment (ROI)

Calibration is often among the most profitable investments an organization can make.

For example, consider a potato products manufacturer that must heat millions of gallons of water each year to a specified temperature range. It doesn’t take much inaccuracy of a drifted thermometer to quickly add up to energy expenses which are many times the cost of calibration.

In summary of our discussion of profitability, calibration helps increase profitability and ROI by saving money, increasing production efficiency, and extending the life of equipment.

Calibration improves safety

Accurate measurements assured by calibration can improve safety by helping to maintain the proper environment for certain processes, especially those that are hypersensitive.

Lithium ion batteries manufactured by car companies, phone manufacturers, and others, provide an example of a hypersensitive process that requires precise measurement and control to keep factory workers safe. Lithium-ion batteries must be produced in a place with less than 1% relative humidity as lithium reacts easily with water vapor to form dangerous byproduct chemicals.

Conversely, companies that produce rocket fuel have the opposite requirement – they need high humidity to control static and reduce the possibility of explosion.

Precise environmental measurements assured by calibration of these and many other hypersensitive processes help keep people safe.

Calibration’s role in making your next flight trustworthy and safe

Precision measurements assured by calibration in the manufacture of commercial airplanes is key to ensuring the safety of your next flight. Pete Burgio is the manager of a calibration lab for a major airline. Pete’s job is to calibrate the test and measurement devices used in the manufacturing and servicing of planes to ensure the test and measurement devices are working within tight tolerances and reporting accurately. Pete explains why trust and calibration are critical to the safe operation of commercial planes in this Fluke promotional video:

Video: Why calibration is critical to the safe operation of airplanes

Calibration helps organizations comply with government regulations

The Food and Drug Administration (FDA) and Environmental Protection Agency (EPA) are examples of government regulatory bodies that require precise compliance with regulations.

An example from the FDA would be regulations around the precise chemical makeup of drugs. The test and measurement equipment used to verify accurate measurements and performance of manufacturing equipment that controls the chemical makeup of drugs must be calibrated regularly to help assure accurate measurements and the safety of all those who take the drugs.

An example from the EPA would be regulations around emissions. For example, companies that use mercury in the manufacturing process must calibrate the many sensors that monitor emissions to make sure mercury is not escaping into and harming the environment and all that live within it.

What are the costs and risks of not calibrating?

The costs of not calibrating include increased production costs due to manufacturing errors, false acceptance of non-compliant product and false rejection of compliant product, increased plant shutdowns, premature breakage of manufacturing equipment, and faulty research and development. As demonstrated in the examples above, the costs of not calibrating can be catastrophic.

Personal injury and unnecessary business costs are some of the main risks of not calibrating. Defective products cause thousands of injuries every year in the U.S. There’s even an entire set of legal rules devoted to injury caused by products called “Product Liability Law” which makes it easier for an injured person to recover damages.

Manufacturers have product liability when their product was defectively manufactured and causes injury. And liability often doesn’t stop with the manufacturer. Product liability lies with all sellers of the product who are in the distribution chain including a manufacturer of parts, the assembler, the wholesaler, and the retailer.

In court cases, manufacturers may be required to defend their processes by showing calibration records. If a manufacturer did not use calibration to help assure the production of safe products, it would be exposed to greater financial risk.

Summary / TL;DR

Why is calibration important? Calibration is important because it helps assure accurate measurements and accurate measurements are required for most research, development, and innovation as well as safe and profitable production across virtually all industries of most products and services we use every day.

Because we’re constantly creating new technologies needing more and more precise measurements, the importance of calibration will grow in the future.

With a better understanding and awareness of the importance of calibration, you’ll notice calibration at work in your daily life by simply looking around your community for examples by industry and professional field.

The purpose of calibration is to help assure precise measurements. The benefits of calibration include improving safety as well as saving money and increasing profitability by avoiding the costs of false acceptance and rejection of products, increasing production efficiency, and extending the life of equipment. In terms of ROI, calibration is often among the best investments a company can make.

The risks of not calibrating include personal injury and unnecessary business costs.

In short, calibration is important because it helps keep your world efficiently running, progressive, and safe.

If you ever need something to be grateful for, look at the things around you and be thankful for the quiet role calibration plays in your life.

Keep learning

Not subscribed yet? Join the Fluke Calibration email list – see the benefits and subscribe here.

Related products

Get help

- Customer & technical support

- Speak with a calibration product expert about your equipment needs