Fluke 378 Non-Contact Voltage True-rms AC/DC Clamp Meter with iFlex

Key features

- Measure voltage and current with your clamp jaw

- Faster, safer testing - all without touching a live wire - using FieldSense™ technology

- Power quality indicator shows whether equipment or power line is faulty

- Complete 3-phase voltage and current tests in 3 quick steps

Product overview: Fluke 378 Non-Contact Voltage True-rms AC/DC Clamp Meter with iFlex

Voltage and current measurements with FieldSense™ technology

The Fluke 378 true-rms clamp meter uses FieldSense™ technology to make testing faster and safer, all without contacting a live conductor. You get accurate voltage and current measurements through the clamp jaw. Simply clip the black test lead to any electrical ground, put the clamp jaw around the conductor and see reliable, accurate voltage and current values on the display.

Power quality indicator shows whether a problem is in the equipment or the power line

The 378 clamp meter includes a unique PQ function that senses power quality issues automatically. When making FieldSense measurements, the 378 will detect and display power quality issues, relating to current, voltage, power factor or any combination of the three. Now you can quickly determine if an upstream supply problem exists, or if there is a downstream equipment problem.

Complete 3-phase measurements in quick, easy steps

- Complete 3-phase voltage and current tests in 3 easy steps

- Full set of phase-to-ground and phase-to-phase values calculated and shown on the meter

- No more hand-written notes or complicated math.

Measure extremely high current with iFlex® probe

The included iFlex flexible current probe lets you measure ac current as high as 2500 A. Crowded wiring cabinets and large conductors are easily measured with the iFlex probe.

Easy to see, easy to use with included tools

Your job will get easier when you use the 378 clamp meter. The display turns green when a stable FieldSense measurement is detected. Visual Continuity also provides a bright green screen for easy detection of continuity in noisy work areas.

What's in the box:

The 378 current clamp includes:

- 378 Non-Contact Voltage True-RMS Clamp Meter

- iFlex flexible current probe (18 inches; 48 cm)

- TL224 silicone insulated test leads

- TP175 adjustable length test probes

- AC285 grounding clip (black, quantity one)

- TPAK magnetic hanging kit, with 9 inch (23 cm) hanging strap

- Premium Carrying case

- Quick reference guide

Specifications: Fluke 378 Non-Contact Voltage True-rms AC/DC Clamp Meter with iFlex

| General specifications | ||

| General Maximum Voltage between any Terminal and Earth Ground | 1000 V | |

| Battery | Type | 2 AA IEC LR6 alkaline |

| Life | 200 hour | |

| Display | Dual readout | |

| Automatic Power Off | 20 minutes | |

| Electrical | ||||

| AC Current: Jaw | ||||

| Range | 999.9 A | |||

| Resolution | 0.1 A | |||

| Accuracy | 2 % ±5 digits (45 Hz to 66 Hz) | |||

| Crest Factor (50/60 Hz) | 3 @ 500 A 2.5 @ 600 A 1.42 @ 1000 A Add 2 % for C.F. >2 | |||

| AC Current: Flexible Current Probe | ||||

| Range | 2500 A | |||

| Resolution | 1 A (≤2500 A) 0.1 A (≤999.9 A) | |||

| Accuracy | 3 % ±5 digits (5 Hz to 500 Hz) | |||

| Crest Factor (50/60Hz) | 3.0 at 1100 A 2.5 at 1400 A 1.42 at 2500 A Add 2 % for C.F. >2 | |||

| Position Sensitivity | ||||

| Distance from Optimum | i2500-10 Flex | i2500-18 Flex | Error |

| A | 0.5 in (12.7 mm) | 1.4 in (35.6 mm) | ± 0.5 % | |

| B | 0.8 in (20.3 mm) | 2.0 in (50.8 mm) | ± 1.0 % | |

| C | 1.4 in (35.6 mm) | 2.5 in (63.5 mm) | ± 2.0 % | |

| Measurement uncertainty assumes centralized primary conductor at optimum position, no external electrical or magnetic field, and within operating temperature range. | ||||

| DC Current | ||||

| Range | 999.9 A | |||

| Resolution | 0.1 A | |||

| Accuracy | 2 % ±5 digits1 | |||

| [1]When using the ZERO function to compensate for offsets | ||||

| AC Voltage: Field Sense | ||||

| Range | 1000 V | |||

| Resolution | 1 V (≤1000V) | |||

| Accuracy | ≤4/0 AWG | 3 % ±5 digits (45 Hz to 66 Hz) | ||

| ≥4/0 AWG | 5 % ±5 digits (45 Hz to 66 Hz) | |||

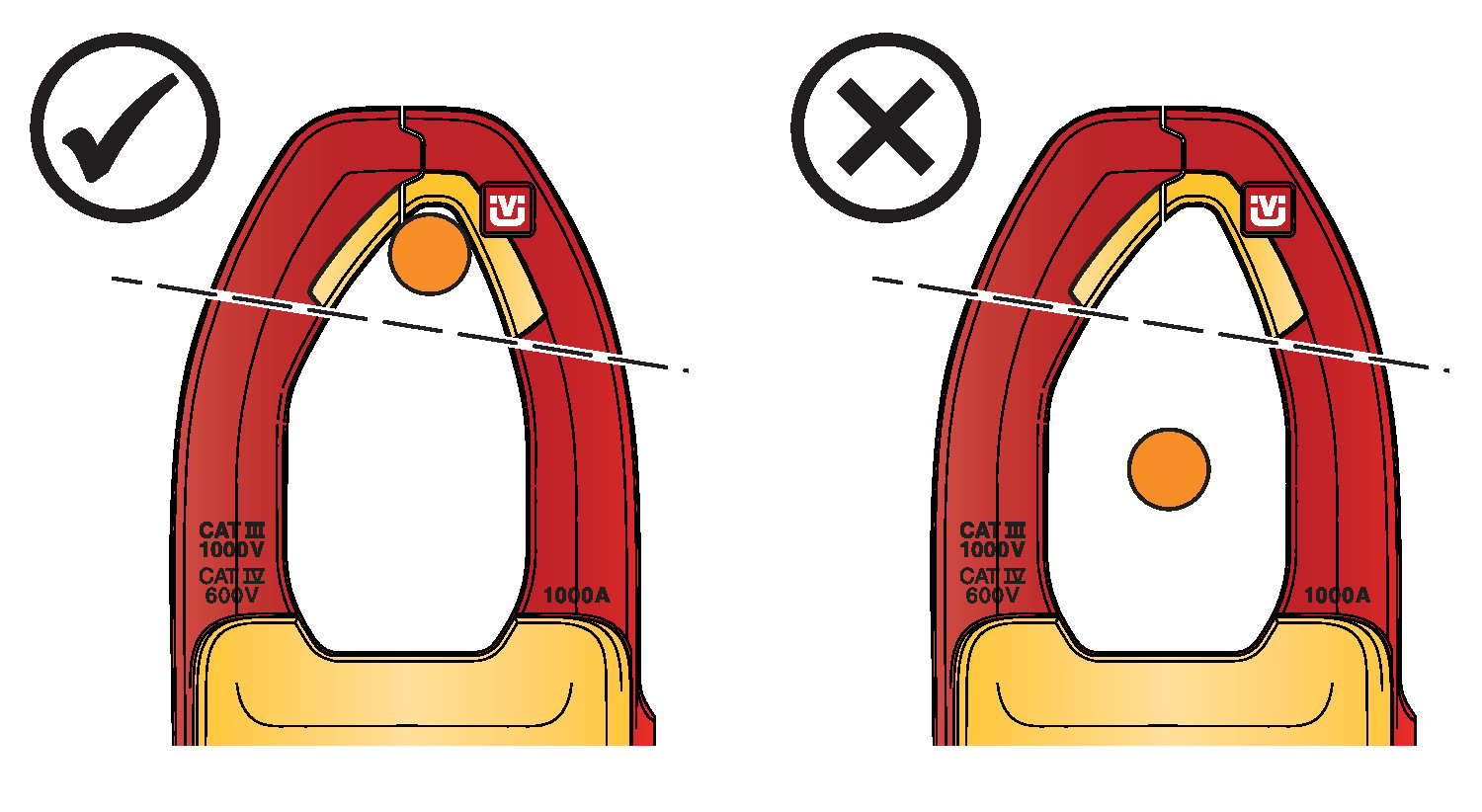

Position wire as close as possible to jaw opening (see illustration).  | ||||

| AC Voltage: Test Leads | ||||

| Range | 600.0 V 1000 V | |||

| Resolution | 0.1 V (≤600.0 V) 1 V (≤1000 V) | |||

| Accuracy | 1 % ±5 digits (20 Hz to 500 Hz) | |||

| DC Voltage | ||||

| Range | 600.0 V 1000 V | |||

| Resolution | 0.1 V (≤600.0 V) 1 V (≤1000 V) | |||

| Accuracy | 1 % ±5 digits | |||

| mV dc | ||||

| Range | 500.0 mV | |||

| Resolution | 0.1 mV | |||

| Accuracy | 1 % ±5 digits | |||

| Amps Frequency: Jaw | ||||

| Range | 45 Hz to 66 Hz | |||

| Resolution | 0.1 Hz | |||

| Accuracy | 0.5 % ±5 digits | |||

| Trigger Level | 5 Hz to 10 Hz, ≥10 A 10 Hz to 100 Hz, ≥ 5 A 100 Hz to 500 Hz, ≥ 10 A | |||

| Amps Frequency: Flexible Current Probe | ||||

| Range | 5.0 Hz to 500.0 Hz | |||

| Resolution | 0.1 Hz | |||

| Accuracy | 0.5 % ±5 digits | |||

| Trigger Level | 5 Hz to 20 Hz, ≥25 A 20 Hz to 100 Hz, ≥20 A 100 Hz to 500 Hz,≥25 A | |||

| Resistance | ||||

| Range | 60.00 kΩ 6000 Ω 600.0 Ω | |||

| Resolution | 0.1 Ω (≤600.0 Ω) 1 Ω (≤6000 Ω) 10 Ω (≤60.00 kΩ) | |||

| Accuracy | 1 % ±5 digits | |||

| Capacitance | ||||

| Range | 1000 μF | |||

| Resolution | 0.1 μF (≤100.0 μF) 1 μF (≤1000 μF) | |||

| Accuracy | 1 % ±4 digits | |||

| Mechanical | ||||

| Size (L x W x H) | 274 mm x 86 mm x 47 mm | |||

| Weight (with Batteries) | 463 g | |||

| Jaw Opening | 34 mm | |||

| Flexible Current Probe Diameter | 7.5 mm | |||

| Flexible Current Probe Cable Length (head to electronics connector) | 1.8 m | |||

| Rogowski Coil Length | 450 mm | |||

| Environmental | ||||

| Operating Temperature | -10 °C to 50 °C | |||

| Storage Temperature | -40 °C to 60 °C | |||

| Operating Humidity (without condensation) | Non condensing (<10 °C) ≤90 % RH (10 °C to 30 °C) ≤75 % RH (30 °C to 40 °C) ≤45 % RH (40 °C to 50 °C) | |||

| Temperature Coefficients | Add 0.1 x specified accuracy for each degree C >28 °C or <18 °C | |||

| Ingress Protection | IEC 60529: IP30 (jaw closed) | |||

| Operating Altitude | 2000 m | |||

| Storage Altitude | 12 000 m | |||

| Electromagnetic Compatibility (EMC) | ||||

| International | IEC 61326-1: Portable Electromagnetic Environment IEC 61326-2-2, CISPR 11: Group 1, Class B | |||

| Group 1: Equipment has intentionally generated and/or uses conductively-coupled radio frequency energy that is necessary for the internal function of the equipment itself. | ||||

| Class B: Equipment is suitable for use in domestic establishments and in establishments directly connected to a low voltage power supply network which supplies buildings used for domestic purposes. Emissions that exceed the levels required by CISPR 11 can occur when the equipment is connected to a test object. | ||||

| Korea (KCC) | Class A equipment (Industrial Broadcast & Communications Equipment) | |||

| Class A: Equipment meets requirements for industrial electromagnetic wave equipment and the seller or user should take notice of it. This equipment is intended for use in business environments and not to be used in homes. | ||||

| USA (FCC) | 47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103. | |||

| Safety | ||||

| General | IEC 61010-1: Pollution degree 2 | |||

| Measurement | IEC 61010-2-032: CAT III 1000 V / CAT IV 600 V IEC 61010-2-033: CAT III 1000 V / CAT IV 600 V | |||

| Current Clamp for Leakage Current Measurements | IEC 61557-13: Class 2, ≤30 A/m | |||

Manuals + resources: Fluke 378 Non-Contact Voltage True-rms AC/DC Clamp Meter with iFlex

- Fluke 377 FC, Fluke 378 FC | Users manual

- Fluke 377 FC, Fluke 378 FC | Quick reference guide

- Fluke 377 FC, Fluke 378 FC | Statement of memory volatility

- Fluke 377 FC, Fluke 378 FC | Safety sheet

- Fluke 377 FC, Fluke 378 FC | Product specification

- Fluke 377, 377 FC, 378, 378 FC | Calibration manual

- Fluke 377, 377 FC, 378, 378 FC | Calibration manual supplement

- Radio Frequency Data Class A | Instruction sheet