According to the U.S. Occupational Safety and Health Administration’s (OSHA) Recommended Practices for Health and Safety Programs, a 50-person plant typically can increase productivity by 13% and save more than $265,000 in faulty products by implementing a rigorous safety and health program.

One safety implementation to consider is the adoption of wireless sensors for remote monitoring. Not only can remote sensors improve your safety program and cut costs, but, as OSHA notes, businesses with lower risks and fewer injuries are also often rated as “best places to work.”

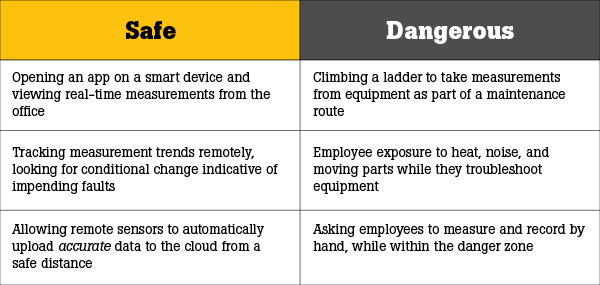

While training to minimize hazards does help, the optimal way to improve team safety is to limit your employee’s exposure to dangerous environments. Wireless sensors stream data to the cloud, reducing the need for planned maintenance routes. Decreasing contact with equipment not only improves safety but increases productivity. By expediting maintenance activity, you help your company lower risk, provide a safe work environment, and improve employee morale.

Case in point: deploying a system of interconnected, IIoT-enhanced devices into your maintenance program can reduce worker interaction with machinery and other hazards.

Fluke sensors for a controlled environment

A key part of the Accelix Connected Reliability Framework, Fluke Connect™ software and sensors provides you with around-the-clock, accurate machine measurements. Continuous data from sensors is uploaded to the Fluke Connect Cloud, where teams can easily access measurements on smart devices, such as mobile phones, tablets, or PC/Mac computers.

Here are details about these remote sensors and software:

- Fluke Connect software: Fluke Connect aggregates, stores, and organizes data, assets, and work orders. Fluke Connect provides real-time and historical data trending, graphing, time-boxing, and reporting. Keep your workforce mobile by accessing Fluke Connect from smart devices wherever there's an internet connection. Integrate your condition data with CMMS Software, for asset health and work-order management.

- Vibration screening: Fluke 3561 FC Vibration Sensors are Chapstick-sized devices that measure vibration and automatically upload data including surface temperature readings to the cloud. Monitoring your equipment for changes in vibration can alert reliability professionals to misalignment, looseness, bearing wear, and imbalance.

- Power monitoring: The Fluke 3540 FC Three-Phase Power Monitor wirelessly measures power variables in equipment and uploads data to the cloud. Current, voltage, frequency, and energy consumption change when equipment experiences load fluctuations. By screening asset performance, reliability professionals can detect premature wear in components.

Interested in how remote sensors can improve safety in your facility?