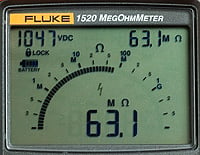

- Measuring tools: Fluke 1520 MegOhmMeter

- Test conducted: Control contacts, line and load circuits, winding phase to phase and phase to ground

- Operator: Buzzell Electric Works motor winding, San Francisco

Buzzell Electric Works serves clients throughout the San Francisco Bay area. Their business: motor repair, rewinding, and service - including onsite and offsite inspections, testing, and consulting. As Matt Buzzell, President, says, "Our job is chasing problems and fixing them."

Buzzell's clients are primarily industrial. The company services motors in printing presses, fire pumps, chillers, elevators, ventilation blowers, and other applications. The clients, from hospitals to high-rise offices, hotels, condominium complexes, and parking garages, are conservative in their maintenance spending and consequently need emergency service.

Mark Toland, Foreman, says, "You might think we take a lot of measurements on a regular basis to keep things running smoothly. Actually, we don't do much predictive maintenance or history work." They do problem call-outs, instead. As Toland says, "When things break, our clients call us."

In facilities that have a "maintain before break" philosophy, insulation resistance test results go into a database for trending. In facilities that have a "run to failure" philosophy, insulation resistance measurements serve a different purpose. Toland says, "We use insulation resistance tests for troubleshooting, as go/no go.

Without these tests, troubleshooting would take longer and cost more. That's not good when production has completely stopped. A breakdown is always an emergency."

While any failure is problematic, motors present additional challenges - because a specific motor failure or its cause isn't necessarily obvious. When a motor stops, it often looks like there's nothing wrong with the motor - at least from the outside. So, the first thing the typical owner does is try to start it back up again. "That's not a good idea," Toland says. "That can result in major damage. We ask the client to wait until we can run an insulation resistance test to see if there's a short to ground. This way, we can prevent additional damage to a unit or related equipment."

Because insulation resistance testing is a critical part of their service, Toland makes a practice of knowing what testers are on the market and evaluating them for use in his business. He says, "It took me eight hours of researching testers just to find one that fit my criteria. The Fluke 1520 MegOhmMeter does everything I need, except capacitance testing."

He was particularly impressed with the safety aspects of Fluke MegOhmMeters. He says, "The Fluke meter will tell you when you have a live circuit. Others don't." Toland agrees. "The Fluke won't apply power to it, either. And the discharge after test is also great."

They also like the low ohms capability on the 1520. "You need to measure winding resistance," says Buzzell. "Very few meters will read less than 1/10 ohm."

Pre-test tasks

Through years of training and experience, Buzzell has developed standard procedures for quickly and accurately identifying motor problems. "When a client calls and says their production isn't running, there's no time for guesswork. We have to know exactly what we are doing."

The first step is basic fact gathering.

Toland says, "We don't just jump in there and start measuring things. We talk to the customer to find out what they've done - maybe they attempted a repair, or made some operational error that led to the breakdown. This effort allows us to focus in the right areas and reduce downtime accordingly."

Next, they visit the motor and gather basic information.

This includes collecting nameplate data and taking measurements with a DMM to understand the environment the motor is operating in. The DMM measurements include voltage, fuse checking, and checking ground connections.

Throughout this process, Toland says, "we use our senses as needed to observe what's going on. A particular smell can speak volumes, if you know what it means. We have a list of things to smell, feel, and listen to."

Control contacts check

Next, Buzzell performs three sets of tests with the insulation resistance tester.

Before testing the motor itself, Buzzell checks the control contacts for quality of contact:

- Lockout and tagout the disconnect to the starter.

- Manually engage the starter, so the contacts close.

- Set the 1520 to the low ohms range.

- Measure the resistance across each set of contacts.

- The reading should be nearly zero. If it's higher than 0.1 ohms, that set of contacts needs to be replaced.

Resistance of line and load circuits to ground

Next, Buzzell measures the insulation resistance of the line and load circuits to ground.

However, "before doing ANY insulation resistance testing, you MUST isolate any electronic controls and other devices from the circuit under test." As Buzzell says, "These voltages tend not to be kind to them." Then:

- Lockout and tagout the disconnect to the starter.

- Set the 1520 to the appropriate test voltage (250, 500 or 1000 V).

- Identify the resistance between these points:

- Line side of starter to ground

- Load side of starter to ground

To pass these tests, the line and load circuits need to show high resistance. "As a general rule, AC devices need a minimum 2 megohms to ground and DC devices need 1 megohm to ground to ensure safe operation," Toland says.

Note: Different companies have different threshold minimums for insulation resistance on used equipment, ranging from 1 to 10 megohms. Resistance on new equipment should test much higher - from 100 to 200 megohms.

If the load side resistance values are acceptable then proceed to the next test. If they aren't, then start tracing the problem: is the insulation breakdown in the load side of the starter, the cables, or the motor?

Winding resistance phase to phase and phase to ground

Buzzell conducts the third set of tests at the motor, measuring the winding resistance phase to phase and phase to ground.

Because he's performing troubleshooting rather than predictive maintenance, Buzzell isn't storing and trending measurement data, to determine whether insulation is degrading. Instead, he's taking "point in time" measurements.

Good results:

- Balanced comparative low resistance values on all three stator phases

- High resistance values on the phase to ground insulation test

Problems:

- Gross resistance deficiencies, such as a phase on phase short.

- Any winding to winding resistance imbalance. If the readings differ by more than a few percent, the motor is probably unsafe to energize.

Integration

There's no magic bullet test that will tell you whether your motor is good or bad. Matt Buzzell says, "Every test by itself is inconclusive until you do them all. Just because you have a good reading doesn't mean something isn't still wrong. But a bad reading means something is definitely wrong."

Here's the full sequence, from start to finish

- Conduct a visual and smell inspection, interview the client and check the nameplate.

- Use a multimeter to check the supply voltage, then the voltage past starter contacts.

As Toland says, "It would be irresponsible to risk a fire from a possibly shorted motor."

If the supply is good, then there's a motor problem. Then, run the following tests.

A. Insulation to ground

B. Balanced phase to phase resistance (3 measurements for 3 phases)

C. Quality connections - motor to service panel.

If any of these elements - multimeter measurements, insulation resistance testing, trained visual inspection - is missing, the results are inconclusive.